Gear Shift Control

Gearshift Control Function Setup

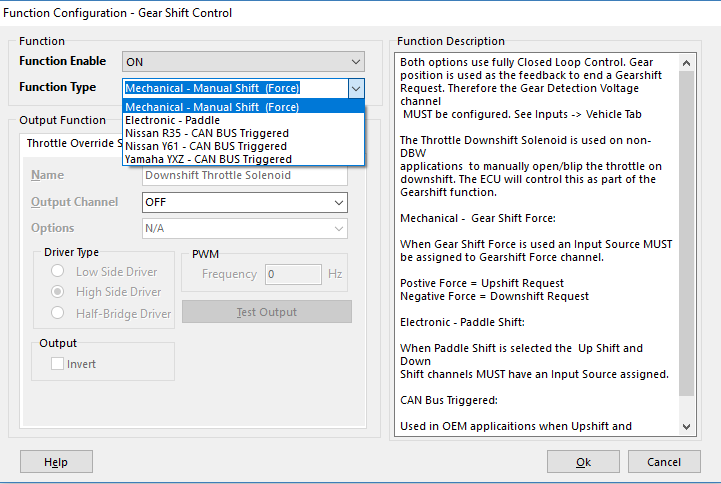

Emtron has multiple methods of Gearshift Control

- Config, Function Setup, Motorsport, Gearshift Control

Mechanical - Manual Shift (Force)

Electronic - Paddle

There are also other CAN BUS Triggered modes for Application Build versions.

** See those Application Build Manuals for details

- Configure Gear Position using the “Gear Detection Voltage” channel . This is normally a barrel position sensor located on the sequential gearbox. See Config View -> Inputs -> Vehicle Tab

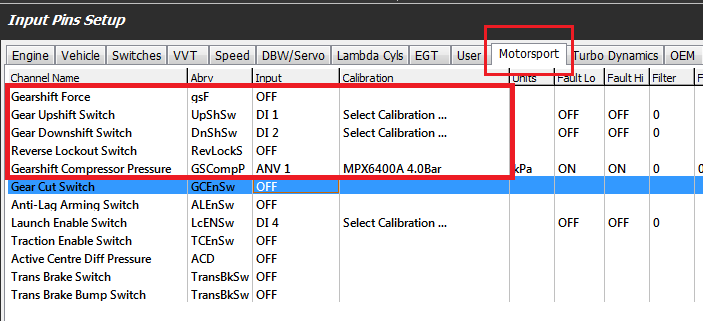

- Configure the Inputs. Configure the following from the Inputs -> Motorsport tab:

Paddle Shift mode

-

- Upshift Paddle Input

- Downshift Paddle Input

- Reverse Lockout Switch if required

- Compressor Pressure Input if required

In Force Shift mode

-

- Gearshift Force Input

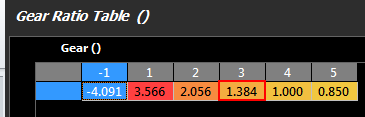

- For Paddle Shift to function correctly and safely at least least two(2) gear channel needs to be tracked for redundancy purposes. Commonly a Gear Detection voltage will be reported from a gear drum mounted to the transmission along with a speed sensor which may be used by the ECU to calculate the gear along with generating Engine Speed requests fro rev-matching limiters. The vehicles wheel diameter and final drive ratio should be confirmed correct. Then enter the correct transmission gear ratios into the table :

See Vehicle Dynamics->Vehicle Main The gear ratio table needs to be accurately set for this to occur.

. See Tuning view -> Vehicle Functions -> Vehicle Dynamics menu -> Transmission Gear Ratio table. Use -1 for Reverse.