Boost Control

Boost Control

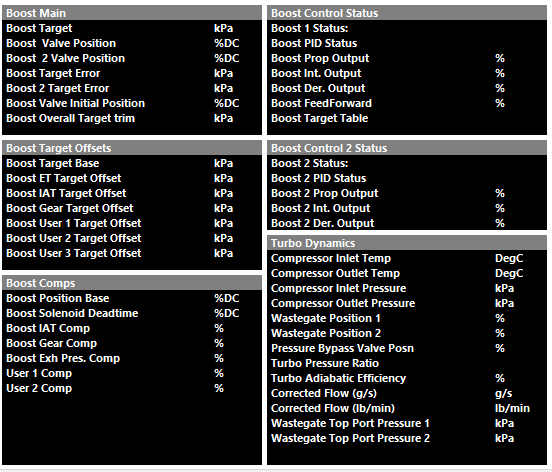

The following calculated runtimes are generated by Emtron that are Boost Control related (to be further discussed more specifically):

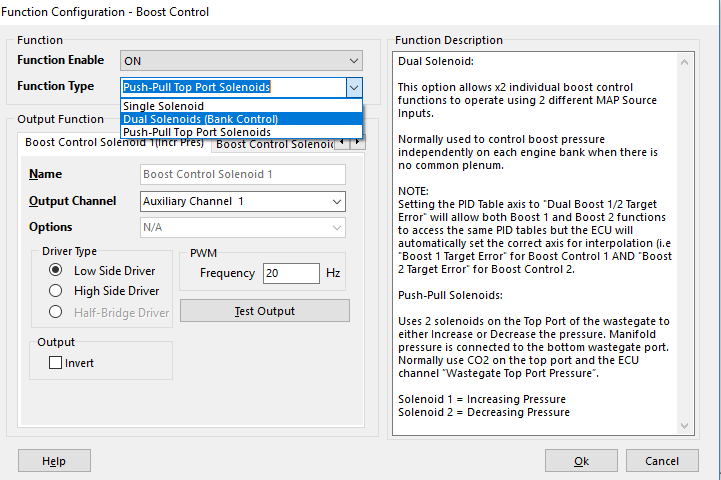

Boost Control Function Setup

Emtron has three methods of Boost Control

- Config, Function Setup, Engine Functions, Boost Control

Single Solenoid

Control of a single solenoid

Duel Solenoids (Bank Control)

Control of dual solenoids in Bank Configuration)

This option allows x2 individual boost control functions to operate using 2 different MAP Source Inputs.

Normally used to control boost pressure independently on each engine bank when there is no common plenum.

NOTE:

Setting the PID Table axis to “Dual Boost 1/2 Target Error” will allow both Boost 1 and Boost 2 functions to access the same PID tables but the ECU will automatically set the correct axis for interpolation (i.e “Boost 1 Target Error” for Boost Control 1 AND “Boost 2 Target Error” for Boost Control 2.

Push-Pull Top Port Solenoids

Uses 2 solenoids on the Top Port of the wastegate to either Increase or Decrease the pressure. Manifold pressure is connected to the bottom wastegate port.

Normally use CO2 on the top port and the ECU channel “Wastegate Top Port Pressure”.

Solenoid 1 = Increasing Pressure

Solenoid 2 = Decreasing Pressure

** Note

Some solenoids are sensitive to flywheel diodes on ECU outputs regarding Boost Control and must be matched appropriate.

Standard MAC valve Aux Output – Aux 1-16 – Low Side

AMS/Bullet type valve – Spare Fuel/Ignition channel – Low Side

** Valves that need to be ran at higher frequency, or in the case of Push-Pull functionality, where the valves must not float - require non-flyweel controlled outputs (Fuel/Ignition channels) to ensure the control function is appropriate

See KV Series Hardware Manual section 3.52