Sync Position %

Sync Position %

Sync position refers to the point in which the ECU is identifying the Sync Edge location. This reference point can be critical as if there is any discrepancy to this position mechanically (wandering between the crank and cam trigger due to slack in cam belt/chain), it can cause crank/sync errors, engine cycle change, or even the firing order to change (especially in the case of non-missing crank trigger setup).

Emtron calculates the following channel for monitoring, diagnosis, and logging purposes - Sync Position %

The Sync Position % is calculated by factoring the position of the Sync Edge between consecutive Crank Teeth.

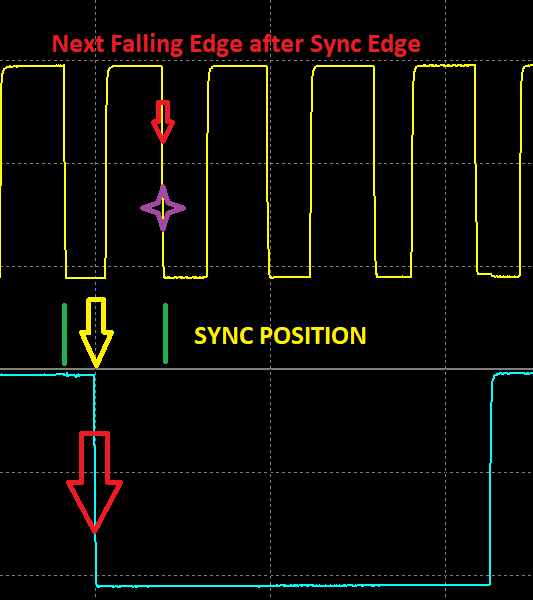

Looking at falling edges, the distance between crank teeth can be identified by the green lines, and the sync edge is identified by the yellow arrow. The value would be Sync Position % - 33% approximately in this case.

Best practice is to aim for a Sync Position % - 50%.

** Note - The higher the crank tooth count, the less resolution this runtime generally will have. IE a 60-2 trigger will have a much more unstable Sync Position % value vs a 1-Tooth Per TDC