RPM Control: Retard (PID) >Cutting (PID)

RPM Control: Retard (PID) >Cutting (PID):

Balancing “Torque Reduction – Retard” vs “Torque Reduction – Cut” is important when using both static and moving target modes for PID Launch Targeting.

Generally, timing retard is good for control of torque and can also help spool turbines in those applications.

However, during launch, as engine load/boost increases the potential engine torque, ignition timing can/will continue to retard to overcome engine speed from increasing.

** EGT, Turbine speed, and boost pressure must be considered, to determine the Static/Moving Ignition Retard Clamp points in their respective tables.

At these points of ignition trim/retard, the Launch system will switch to Launch Torque Reduction – Cut functions.

See:

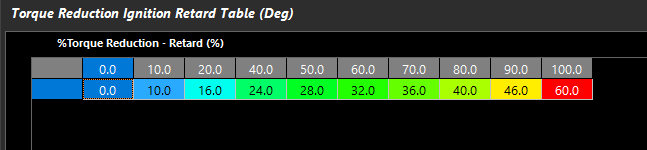

Torque Reduction Ignition Retard Table:

Engine Functions -> Torque Management -> Torque Reduction Ignition Retard Table

The runtime %Torque Reduction – Retard is used.

The channel correlates to how much retard will be applied vs the amount of Torque Reduction requested.

This is a global function of the ECU, which is why it is under the Torque Management section.

** Warning - The maximum value in this table (at 100% %Torque Reduction – Retard), must be at a higher value than the Static/Moving Ignition Retard Clamp

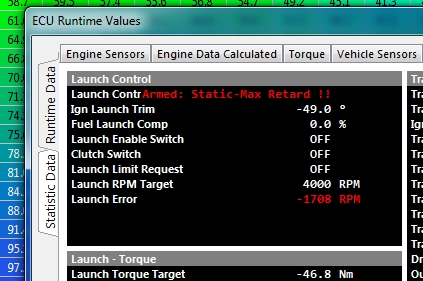

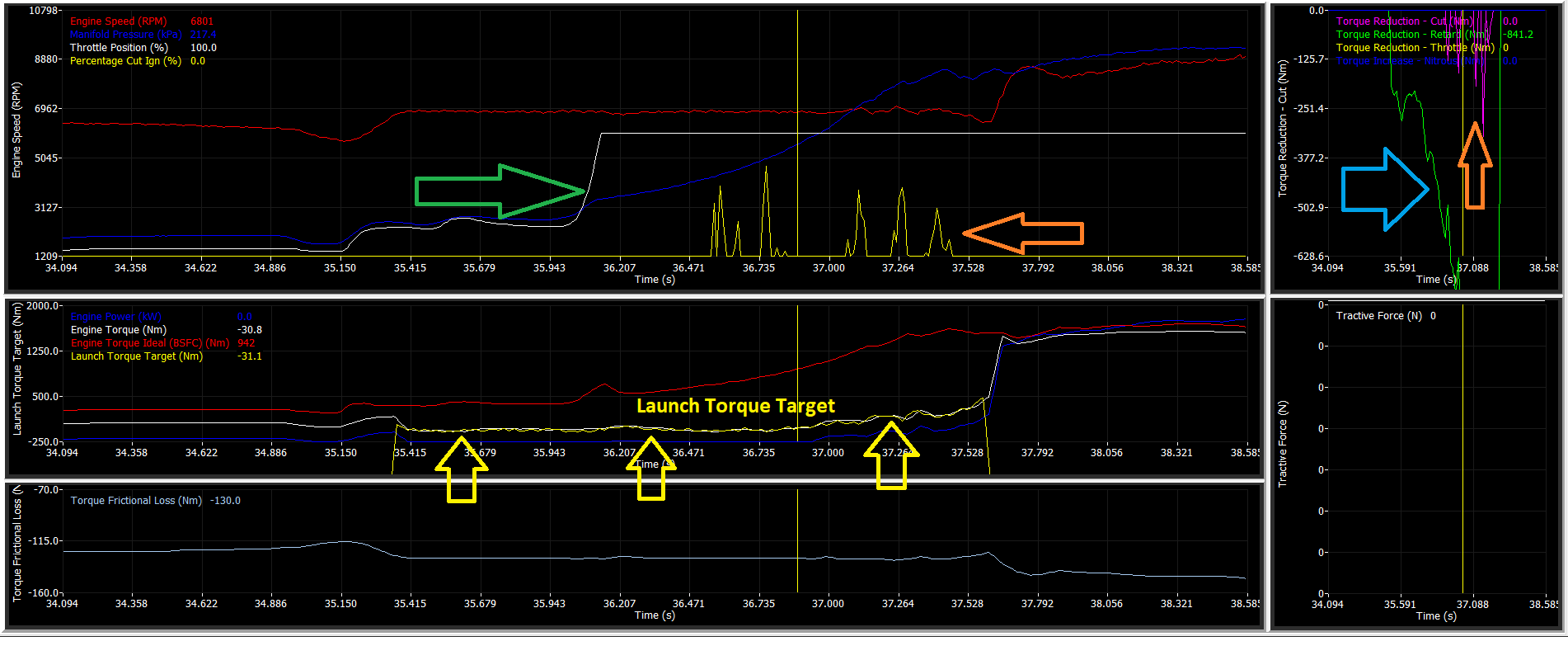

Static Mode Example Data:

In the above static example, you can see the ECU holding the “Launch Torque Target” (Yellow Arrows) in the second plot.

This is done by Torque Reduction – Retard (Blue Arrow), until the load is increased by throttle and boost (Green Arrow).

The Launch Control system automatically controls the Launch Control Target with the required additional Torque Reduction Cut under the higher loads to control the Launch Torque Target (Orange Arrow).

Cuts are introduced once the Static Ignition Retard Clamp is reached.

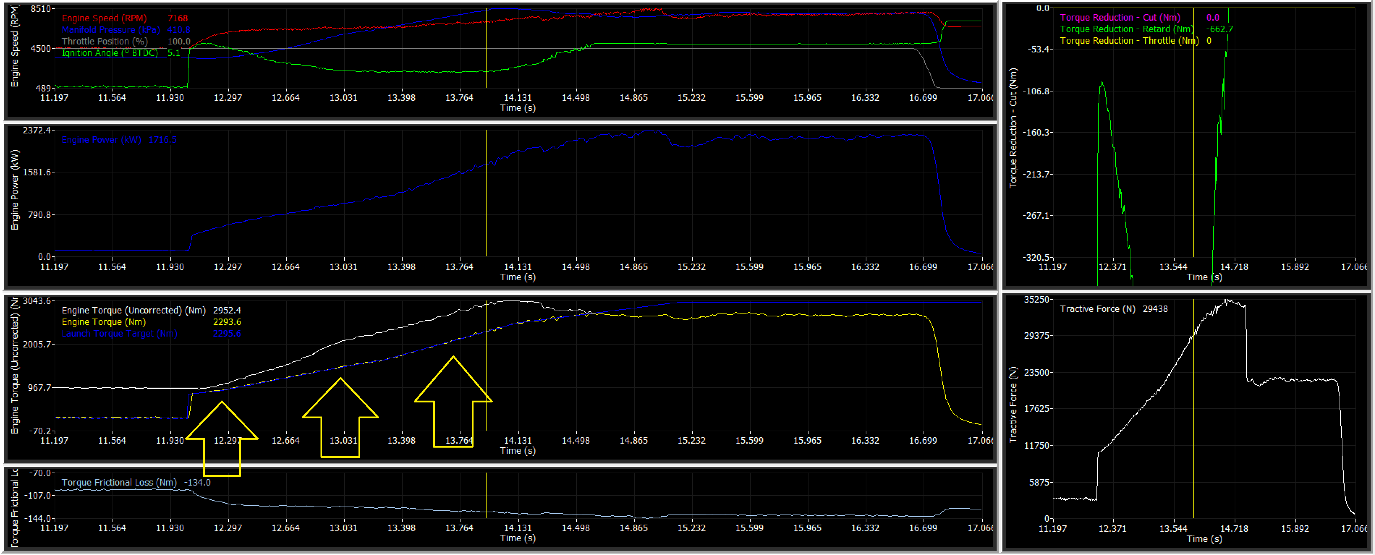

Moving Mode Example Data:

In this moving target example, the ECU is holding “Launch Torque Target” (Yellow Arrows) in the second plot by Torque Reduction – Retard alone.