Gearshift - Paddle

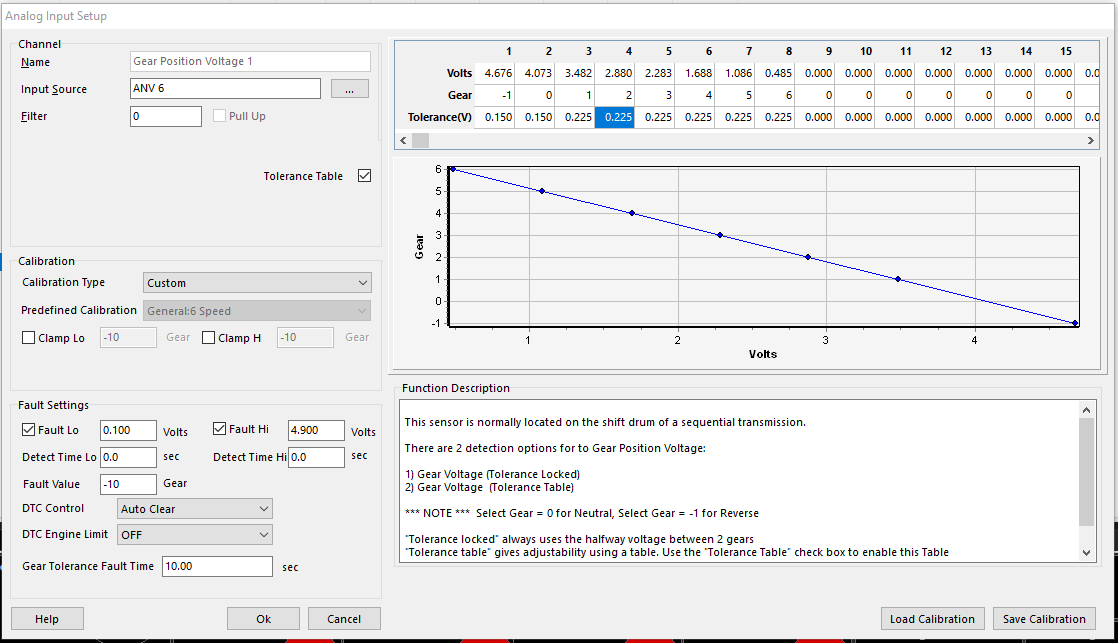

Gearshift without “shift position” – Tolerance Voltage

Larger tolerance voltage number will achieve next gear stable sooner. Consider volt change per gear, to determine tolerance volt.

Gear volt spread is 0.60x volt. 0.225 tolerance will achieve “gear change” 63% of the way through the barrel turn.

This is a way control the shift timing if using “Next Gear Stable” function

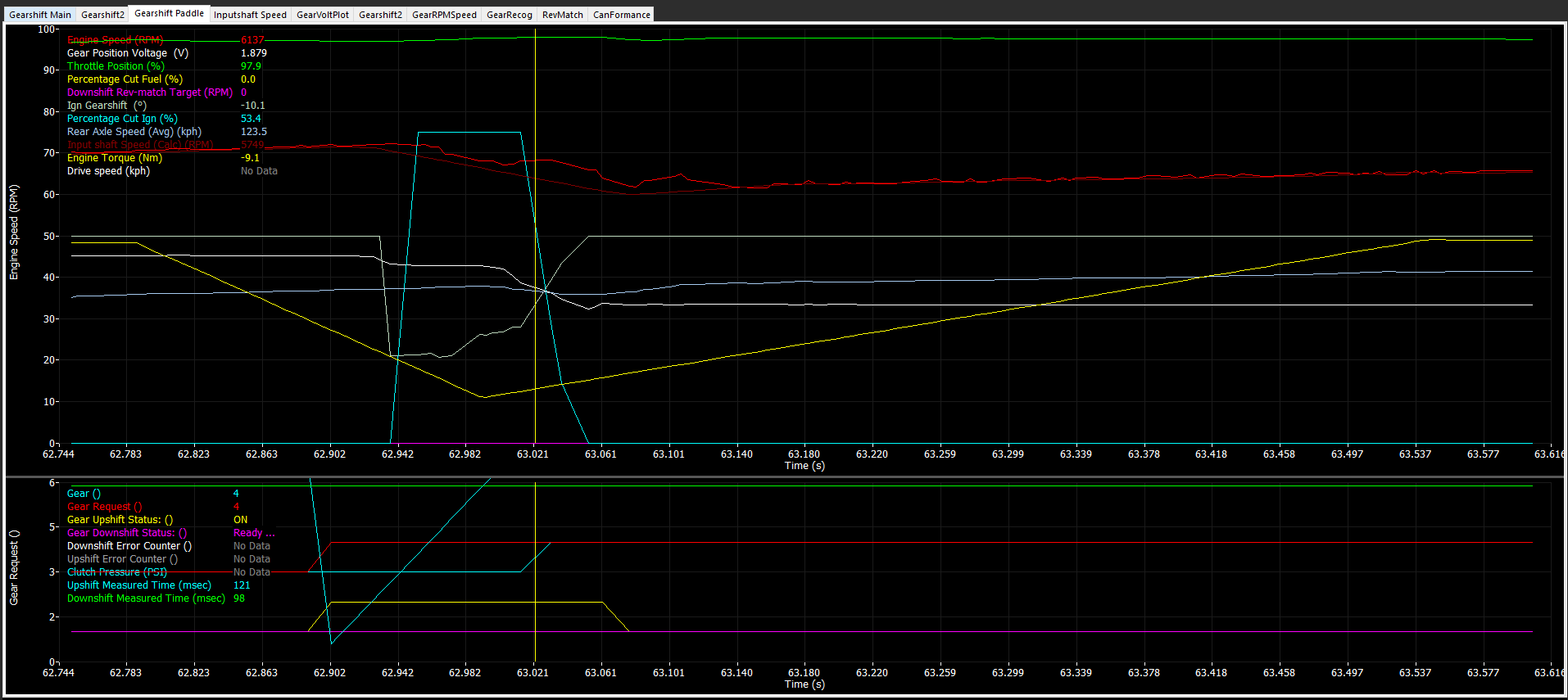

Above example is vehicle using a static cut value (75%).

Next Gear % Cut Level and Ignition Retard Recovery Time are being leveraged to phase back in engine power.

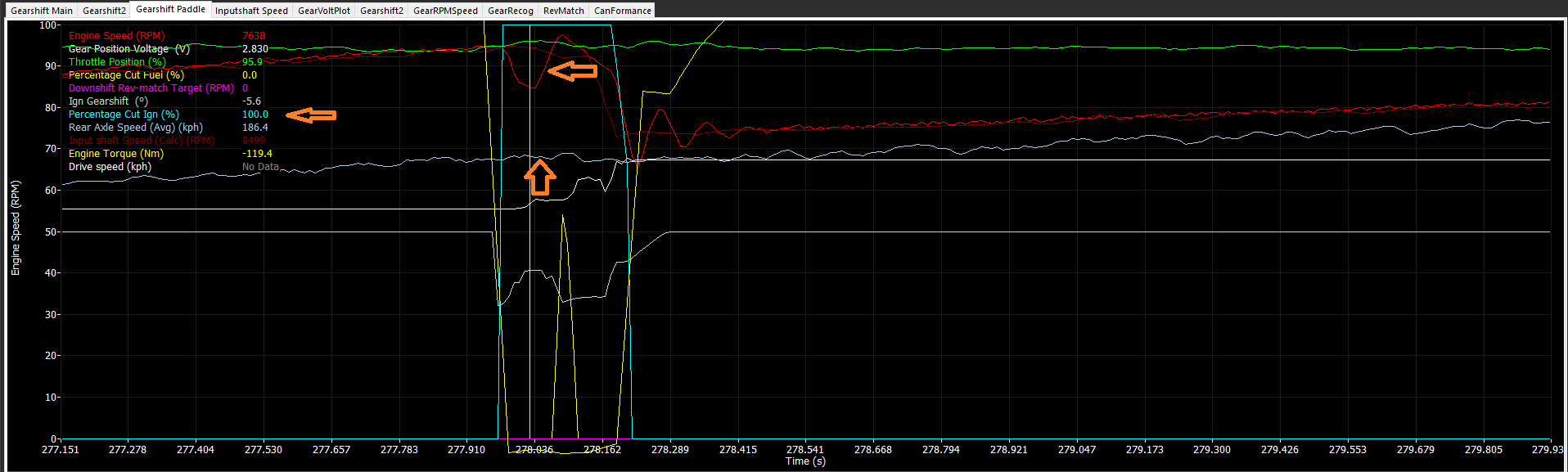

Pre-loading Gearbox

Necessary to achieve swift ratchet action, similar to a “stick” setup where you’d deny cut until a specific force on the shifter.

Mechanical lag of linakge, air lines, etc – all contribute to needing pre-loading.

Cars with high forward momentum will need pre-loading to ensure the middle phase of the gearshift happens at the right time, when the dogs are fully dis-engaged.

Observe engine in full cut off, engine speed decelerating, but speed still increasing. The barrel has not turned at the right time (when the engine speed decelerated) and caught the previous gear deceleration side of the dog hanging the upshift up.

Pre-loading can be done with Torque Reduction Delay table, or if Shift Position is available, in full closed loop ->

Torque Reduction and Re-Introduction

Reduction in torque can be achieved many ways with fuel, ignition, or both cut tables. Retard tables. Rev matching cut functions, and even DBW target hijacking.

Different scenarios will call for different methods of reduction types.

On turbocharged engines, using too much cut may reduce exhaust energy affecting turbine speed.

Too much retard may increase exhaust energy

A global boost control comp for “Ignition Trims Total” is suggested

Re-Introduction of torque is critical to prevent drivetrain from clashing, bouncing on dogs (drive/decel), and creating excessive ringing in the driveline.

Plotting/observing Engine Torque (requires tuned torque model) runtimes can help what the engine is doing during the shift quickly

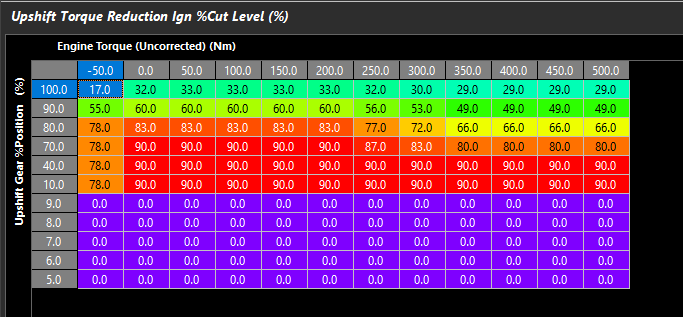

Using Shift Position channels in cut tables

- Cut Recovery Time table functions off values in the cut table – if last value is “0” then recovery time has nothing to recover from

- Tolerance Voltage in the Gear Volt input setup should be considered. Suggest using a lower tolerance voltage to control the ECU through the shift